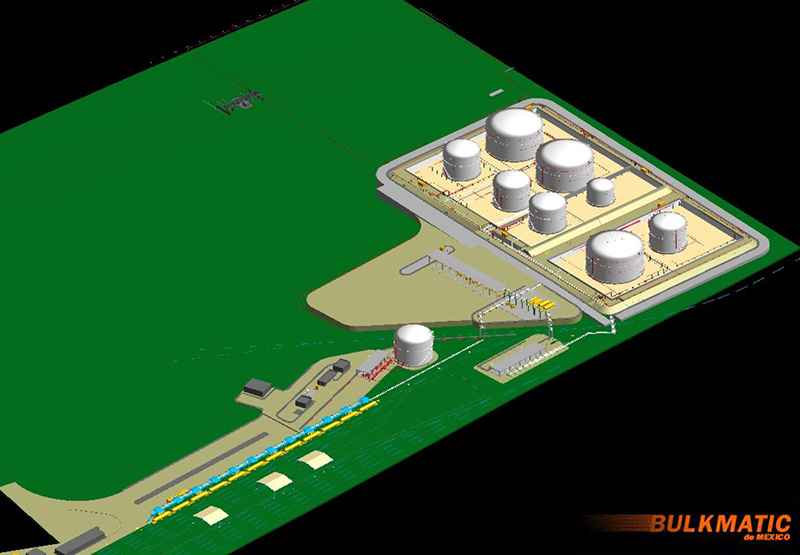

The first private company of fuel storage in the northeast of Mexico.

We started the transloading operations from rail car to trucks on January 2018. We will start storage operations on the third quarter of 2019.

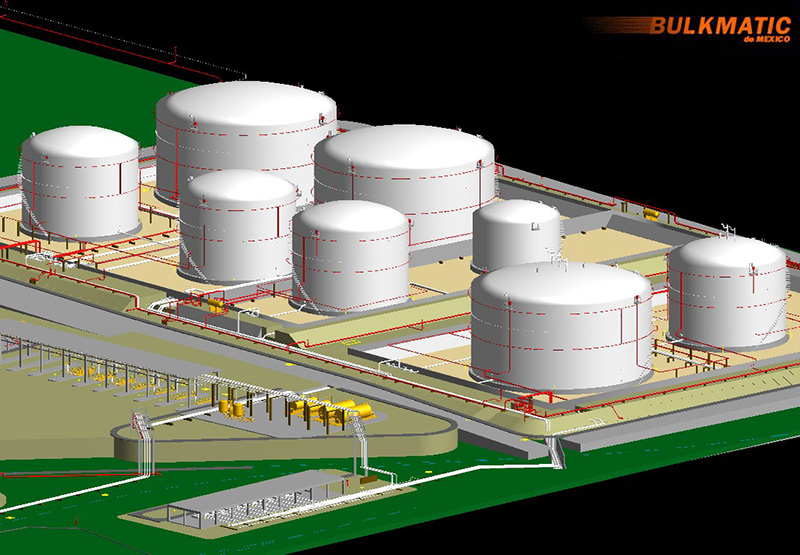

- 690kb of storage for hydrocarbons

- 4 Tank Farms of 60kb (Geodesic roof with internal floating membrane) and 3 Tank Farms of 150kb (Geodesic roof with internal floating membrane).

- 30kb of tank trucks daily loading capacity in 10 positions

- Tracks capacity to receive unit trains with 90 units

- Tracks capacity for transloading operation rail to trucks

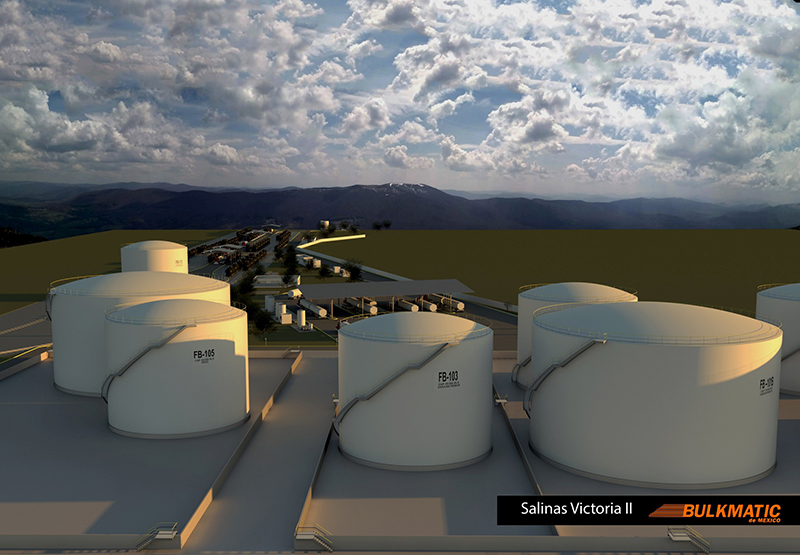

Video SV2, under construction

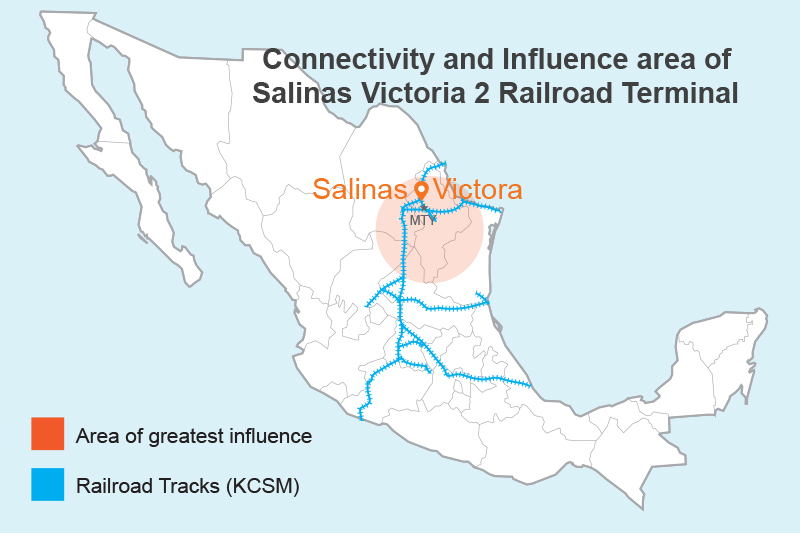

LOCATION

Location:

- Carretera Colombia Km 30.5, Salinas Victoria N.L. Lat. 26°00´56¨ N / Long. 100°17´53¨O / Elevation. 458 m.

- Connectivity:

- Highway Monterrey to Colombia Nuevo Leon (Colombia Border)

- Highway Monterrey to Laredo (Nuevo Laredo Border)

- Northern loop with connectivity to Reynosa (east) and Saltillo (west)

- Highway Monterrey to México City

- Railroad Terminal in Salinas Victoria, Nuevo Leon. Served by Kansas City Southern de Mexico (KCSM).

- Mayor influence zone: Tamaulipas, Nuevo Leon, and Coahuila.

- 50Km to Monterrey

| Distance to main cities: | ||

|---|---|---|

| Monterrey y áreas aledañas: | 50 | Km |

| Saltillo: | 100 | Km |

| Nuevo Ladero: | 200 | Km |

| Reynosa: | 235 | Km |

| Matamoros: | 320 | Km |

| Monclova: | 174 | Km |

| Linares: | 169 | Km |

| Tampico: | 544 | Km |

| Zacatecas: | 481 | Km |

| San Luis Potosí: | 530 | Km |

| Torreón: | 361 | Km |

INFRASTRUCTURE

Land

14 hectares totally fenced with CCTV and survaillance by guards 24/7 plus 1 hectar for tank trucks parking.

Rail tracks and sidetrack

Storage capacity of 260 spots and 2 side tracks of 5 km to receive unit trains of 90 rail cars equivalent to 60kb nominal; tracks for transloading cars to tank trucks.

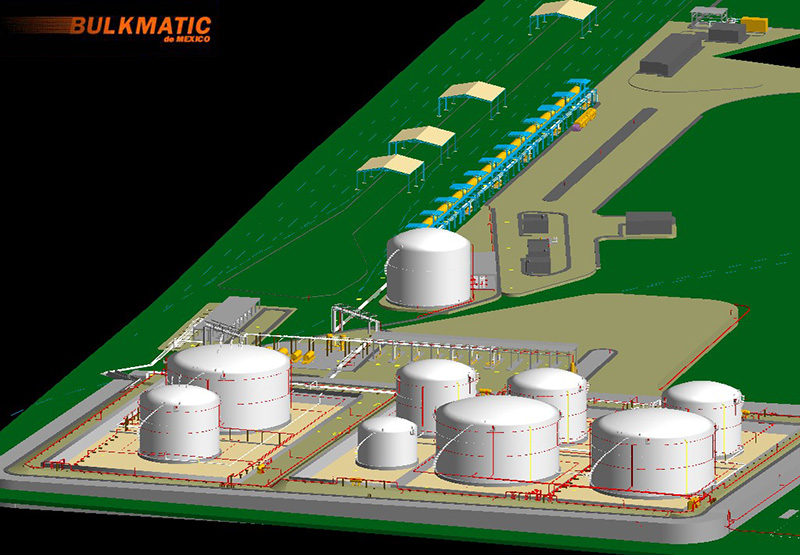

4 tank farms (60kb each) and 3 tank farms (150kb each)

Tanks farm with internal floating membrane each one to store gasolines and diesel received by rail cars and tank trucks;

Total capacity per storage tank is 690kb, protected with contention dikes and industrial drainage.

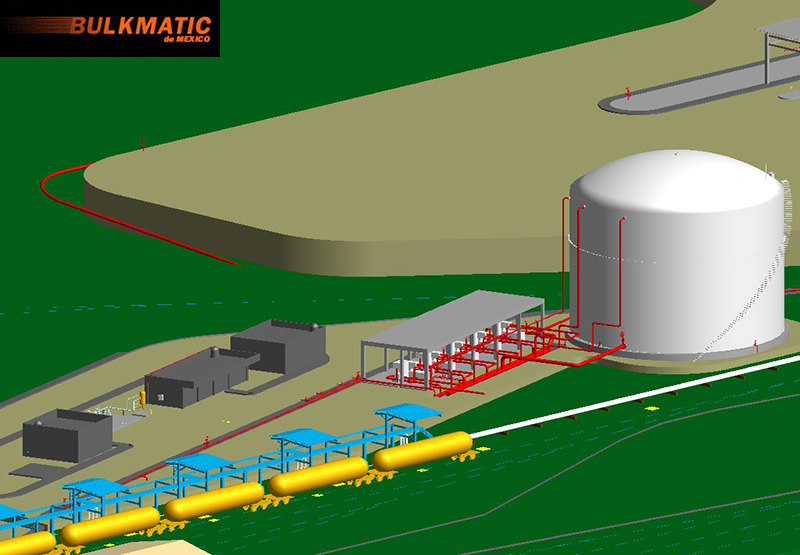

Pipelines

Pipelines to conduct the fuels from rail car unloading racks to the storage tanks through 14-inch pipes, from storage tanks to pumps room through 20-inch pipes and towards 6-inch tank auto cargo racks.

6 rail car unloading stations

To unload unit trains and manifest train directly to the tanks, Unit Train unload time is 24 hours with 6 pumps of 600 GPM capacity.

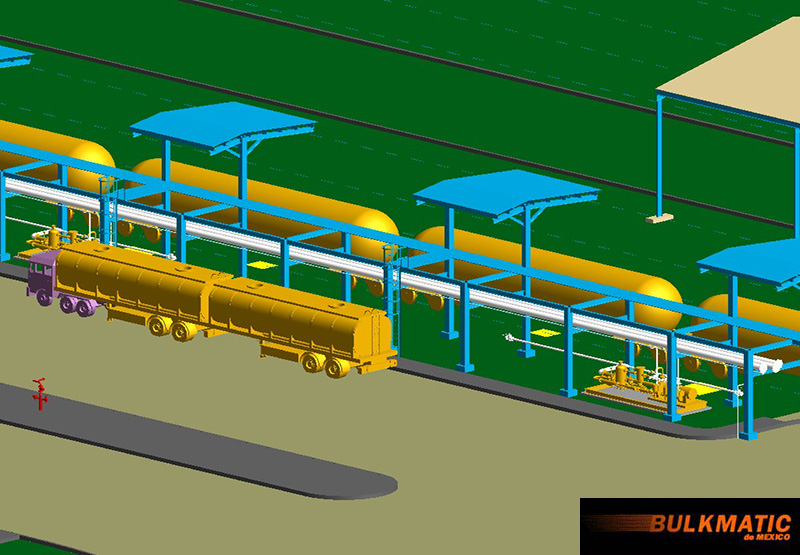

10 tank truck loading stations

With a daily capacity of 30kbd with 10 pumps of 500GPM capacity.

Locomotives and rail car mover

1 Locomotive of 4500 HP

1 Shuttlewagon rail car mover

1 Rail car mover for internal movements

Quality Control Laboratory

Subcontracted Laboratory regulated by the CRE to analyse products at the receipt and in the storage; Laboratory certified by the CRE for control tests of Annex 4 of NOM-CRE-016,2016 and accredited to the EMA in ISO17025.

Vapor recovery system

URV by John Zink in area to load tank trucks.

Automatized Measurement Systems

System of measurement in the receipt of product, in the filling of tank trucks and in levels of inventories in storage tanks.

Additive Injection and Oxigenation System

Tank of additives and injection to tank trucks. Tank of oxygenant of 20kb and mixing system in the loading rack.

SYSTEMS AND SECURITY

Power substation

Electric rooms and electric installation class 1 division 1 in process areas.

Automatic Control Systems

Tank truck loading racks, rail cars unloading racks, telemeter in tanks, pumping system and vehicles access control.

Firewater system

Firewater system with water tanks, foam and pumping, water pipes, monitors, hydrants, suppression system; LEL detectors, fire detectors, and SCADA system.

Information Techonologies

For voice and data, shipping information, and real time transactions.

Drainage Net

Sanitary, industrial, and pluvial drainage.

Alarms

Visual and sound alarms with emergency safety buttons.

FACILITY DESIGN

WHY CHOOSE BULKMATIC?

We are the first storage solution for fuels in Mexico.

MISSION

“Exceed expectations of our customers, shareholders, and employees guaranteeing the best experience of Multimodal Logistic Services.”

INFRASTRUCTURE

- 14 Railroad Terminals.

- Annual traffic of +35,000 rail cars handled in the terminals.

- Over 600 employees.

EXPERIENCE

- Experience in handling hydrocarbons, chemicals, plastic polymers, and food grade commodities.

- 35,000 bulktruck deliveries annually.

- Highly Qualified Personnel.

QUALITY SERVICE

- Excellent relationship with Mexican railroads.

- Loyal relationships with Mexican and global customers.

- Compliance with the Mexican Normativity.

- Certified quality control.

CUSTOMER SATISFACTION SURVEY 2017:

- 92% says that Bulkmatic meets its customer expectations.

- 97% would recommend Bulkmatic.

Main reasons to hire BULKMATIC:

- Infrastructure.

- On time deliveries.

- Security and EHS.

Key hits:

- Ethics in business.

- Certifications.

- Compliance with regulation.

Source: Customer Satisfaction Survey - Bulkmatic de Mexico - B.E.S.T. 2017

CERTIFICATIONS

ISO9001

28001:2008

SARI